Assembly

Some products require assembly and packaging services according to customer requirements

Post Processing

After mass production, Will do post-processing including logo printing, painting, plating, laser engraving, ultrasonic welding etc.

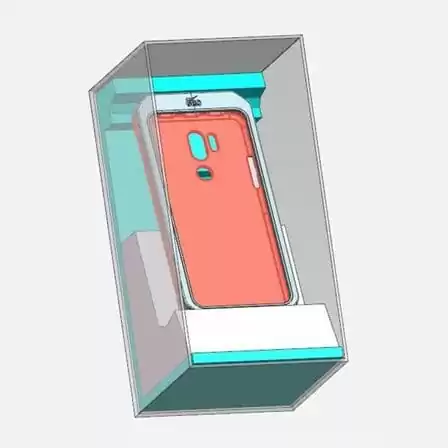

Product Produce

After injection mold making finished, we will send the test samples to customer for comfirmation, and then start the mass production

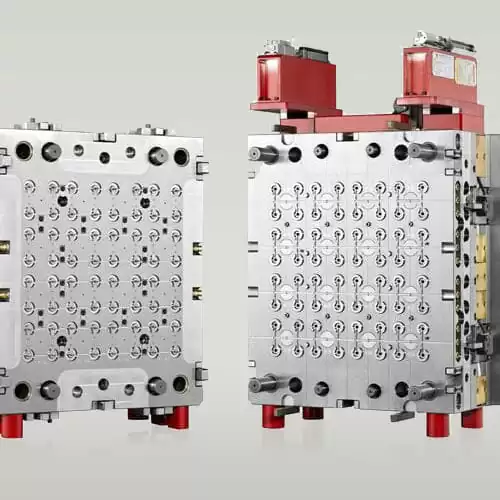

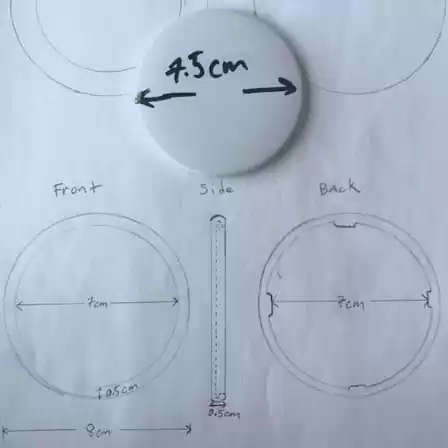

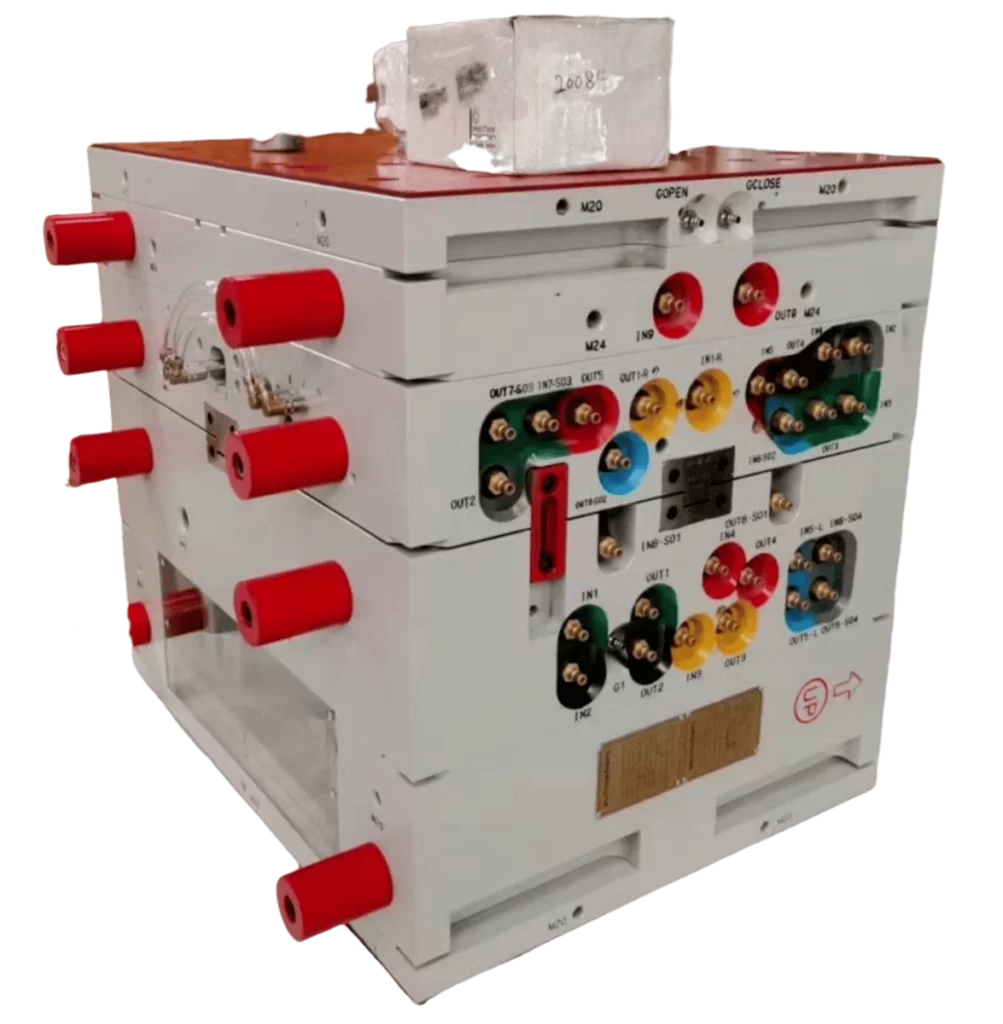

Injection Mold Making

After the 3D design of the mold confirmed, the injection mold maker will starts the injection mold making