We use silicone materials to make different silicone products, the hardness of the silicone chosen, and the operation process is different. Take liquid silicone material, for example, the hardness of silicone can be as low as 0 degrees or less, as well as 0 degrees to 60 degrees.

The unit of silicone soft hardness is (Shore A). If you require good tear resistance hardness, you can choose between 10-45A, depending on what products are used.

There are a variety of silicone rubber products on the market, each with a different level of hardness. It can be difficult to decide which product is best for your needs, but by reading this article you will be able to choose the perfect silicone product for yourself.

Dental mold silicone

Dental mold silicone rubber comes in a wide range of hardnesses, from very soft to very hard. The hardness of the material will determine the level of detail that the mold can capture, as well as the durability of the mold.

Softer silicones are often used for intricate designs, while harder silicones are better suited for more robust molds. The type of silicone used will also determine how long it takes to set; softer silicones will set faster than harder silicones. Ultimately, the decision on which silicone to use will depend on the specific needs of the project.

For those who do not understand silicone materials, the physical softness and hardness of silicone products are half-understood psychologically, looking at the appearance of the product is no change, need to understand the relationship between the formulation and various physical properties to understanding.

However, for customers who first come into contact with silicone rubber products, there will be uncertainty about the softness and hardness of the silicone parts we use if they do not understand the softness and hardness of silicone.

Therefore, it is easy to lead to the demand for silicone rubber products in the custom silicone products, do not know how the hardness to better fit with the product, so the latter will have to be adjusted to the silicone hardness.

Candle silicone

The hardness of the candle silicone is an important consideration when choosing a candle mold. The hardness of the silicone determines how easy it is to get the candle out of the mold.

For example, a softer silicone will produce a more detailed candle, but it may be more difficult to release. A harder silicone will produce a smoother candle, but it may break or fracture more easily.

When choosing silicone for candles, it is important to consider the intended use of the candle and to choose a hardness that will produce the best results.

Different silicone rubber products have their unique properties and process requirements, such as silicone seals for silicone product manufacturers, silicone accessories, etc. The most suitable polymer can be selected for blending.

In the softness and hardness to achieve a close fit sealing shock absorption, waterproof and oil-proof and other effects, the physical properties of the softness and hardness of silicone products.

Plaster mold silicone

The hardness of plaster mold silicone rubber refers to the amount of pressure required to form indentations on the silicone rubber. The higher the hardness, the greater the pressure needed. Plaster mold silicone can be used for a variety of applications, including medical devices, food-grade products, and cosmetics.

Plaster mold silicone comes in a wide range of hardnesses, from very soft to very hard. The hardness of plaster mold silicone can be adjusted by adding or removing curing agents.

Plaster mold silicone is a durable and versatile material that can be used for a variety of applications. Most of the silicone rubber products are made of silicone blends, and most of the molding process is also oil pressure molding.

The lower the hardness is not only unfavorable to the product placement, but also generates bubbles in the process of high-temperature vulcanization because of its semi-liquid internal structure, so we will have very high requirements for the selection of silicone materials for these products.

And also must use the best vulcanizing agent, which is solved by increasing the power of the vacuum machine and improving the mold structure The best vulcanizing agent must also be used.

The toughness and elasticity of silicone rubber products are very good, and not easily affected by external forces, which is because the surface layer will spray a layer of grease-like substances, touching the feel will be a little smoother.

Mainly used in engineering machinery, automobiles, electronic products, household appliances, toys, medical, sports equipment, and other industries, with shock absorption, anti-static high and low-temperature resistance, wear resistance, sealing, flame retardant, alkali corrosion resistance, and other roles.

Food-grade silicone

Food-grade silicone rubber is a reliable and safe material for food handling and preparation. Its low hardness means it won’t damage fragile items like bread, while its high heat resistance means it can withstand boiling water and be placed in the refrigerator.

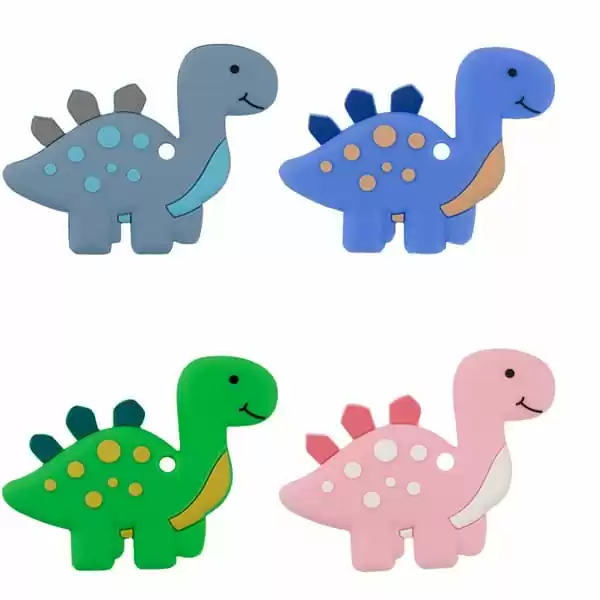

Food-grade silicone rubber is also resistant to stains and odors, making it easy to keep clean. Its ease of cleaning is one of the reasons food-grade silicone rubber is often used in baby products, as it helps prevent the spread of bacteria.

In addition to its safety and practicality, food-grade silicone rubber is very versatile. It can be used to make a wide variety of kitchen tools, from spatulas and chefs to ice cube trays and cake molds. Therefore, food-grade silicone rubber is a must-have material for any kitchen.

When we use liquid silicone to make silicone rubber products, we all need to adjust the hardness of the silicone according to the characteristics of the product we are making, and by hardness, we mean the hardness that the additive liquid silicone has after curing. Silicone has one characteristic: it is very soft.

However, there are occasions when it needs to be hardened, and a common method of hardening is to add MQ resin to the silicone rubber. There are many different uses and different hardnesses required.

For example, for chocolate molds, a hardness of 10-20 degrees is required, and for erotic products, a hardness of 0 degrees – below 0 degrees is required. In addition, the harder the silicone, the more brittle the product, the poorer the performance, and may crack as soon as broken.

For example, 0-5 degrees (including 0 degrees below) plus molding liquid silicone, the product feels super soft to the touch, and human skin hardness is about the same. Suitable for adult products, chest pads, shoulder pads, patches, non-slip pads, and other flexible silicone rubber products, simulation of the human face mold, and simulation of human limb shape.

Human body silicone

Human silicone hardness is a measurement of the hardness of silicone rubber. It is usually used to test the hardness of medical-grade silicone rubber, medical-grade silicone rubber can be used for implants and prostheses.

The test method is to use a hard object (such as a steel ball) to press into the surface of the silicone rubber. The indentation is then measured and the hardness is calculated from the depth of the indentation.

The hardness of human silicone rubber is usually expressed in terms of Shore A hardness. The Shore A scale ranges from 0 to 100, with 0 being the softest and 100 being the hardest. Medical grade silicone rubber is typically between 40 and 50 Shore A hardness.

Conclusion

When it comes to silicone rubber products, there are many factors to consider. By understanding the different types of hardness and how they affect your product, you can choose the right silicone for your needs.

We offer a variety of silicone rubber products in different hardnesses, so we are confident that we can help you find the perfect material for your project. Contact us today to learn more about our products and to get started on your next silicone rubber project!