High-temperature vulcanized silicone rubber

High-temperature vulcanized silicone rubber has many unique and excellent properties that ordinary rubber does not possess. It has been widely used in various fields of national economy such as life.

The application products of high-temperature vulcanized silicone rubber mainly include;

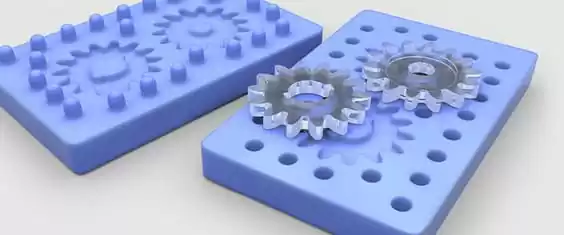

Molded products: various rubber sheets, gaskets, gaskets, films, rubber spokes, keys of electronic appliances, various mold rubber products for special occasions, etc.;

Extrusion system: such as various rubber hoses, rubber ropes, profiles, wire and cable sheaths, rubber strips, etc.;

Tape products: such as gaskets, diaphragms, self-adhesive cloth, isolation cloth, etc.

1. Electronics industry

The rubber material of choice in the electronics industry. Mainly because high-temperature vulcanized silicone rubber is resistant to high and low temperatures, has excellent electrical properties, and performance remains unchanged in a large temperature range and electrical frequency range.

The application of high-temperature vulcanized silicone rubber products can ensure the stable performance, safety, and reliability of electronic appliances.

Application products include electrical connectors, electrical seals and shock absorbers, high-temperature potentiometer seals, etc.

Conductive high-temperature vulcanized silicone rubber with conductive fillers (such as carbon black, metal powder, etc.) can be used as conductive connectors (electronic computers, remote control systems, buttons for electric toys and telephones, conductive connectors for electronic watches, etc.).

With stable performance, the displayed numbers are accurate; Conductive silicone rubber products are also widely used in microwave ovens, fax machines, and leadless integrated circuits. A lot of silicone rubber products are also used on TV sets, and the high-voltage caps of TV sets are made of silicone rubber.

2. Wire and cable industry

Silicone rubber is an ideal insulating material in the wire and cable industry. High-temperature vulcanized silicone rubber has high-temperature resistance, ozone resistance, weather resistance, and excellent electrical properties.

When it is burned and decomposed, the silica residue generated still plays an insulating role; it also has good thermal conductivity and can quickly remove the heat generated by the current load; its arc resistance is very excellent.

The wires and cables used in high-temperature vulcanized silicone rubber mainly include power cables, ship cables, heating cables, ignition cables, atomic energy device cables, aviation wires, etc.

Adding aluminum hydroxide filler to silicone rubber used in high-voltage insulated lines can improve the properties of silicone rubber such as tracking resistance, electrical corrosion resistance, and arc resistance.

3. Auto industry

Rubber products such as bushings, cushions, belts, protective covers, caps, and sealing rings near the engine and transmission need to withstand a temperature of 175 ° C, and some places need to withstand high temperatures above 300 ° C.

In such occasions, general organic rubber is no longer applicable, and silicone rubber is required. Silicone rubber is also used in sealing high-temperature furnaces, structural components of low-temperature refrigerators, conveyor belts for hot products in metal processing, and hot glue spokes.

4. Aerospace

Launch vehicles, space shuttles, spacecraft, satellites, etc., operate in harsh, complex and harsh space environments, so the materials used must be able to withstand ultra-high and low temperatures (-75-200°C) for a long time, ozone, Radiation resistance, aging resistance, flame retardant, etc. So only silicone rubber can do the job.

The silicone rubber products used in this field include various rubber hoses, sealing gaskets, gaskets, cups, valves, shockproof parts, hot air ducts, switch sheaths, oxygen masks, fire barriers, and hoses for instruments and meters. , cushions, wires, cables, plugs, sockets, switch buttons, etc.

5. Medical and health field

Because silicone rubber is non-toxic, has good biocompatibility, and has good physical and mechanical properties, it can be sterilized without damage at high temperatures, so it has more and more applications in the medical field.

Such as blood vessels, various intubations, chest drainage tubes, plastic surgery and repair materials, artificial skin, implant intervention materials, drug release systems, biosensors, etc.

Various human organs can also be made, such as artificial throat, artificial lung, retinal implant, the spherical mitral valve of artificial heart, esophagus, trachea, artificial joint, artificial limb, etc., which can be placed in the human body to perform the function of the organ.

For example, a patient whose larynx has been removed is put into an artificial larynx, and the functions of speaking, eating, and breathing can be restored quickly without any abnormality.

The application of silicone rubber in the medical and health field can be classified into the following categories: long-term indwelling organs or tissue substitutes in the human body; short-term indwelling medical devices in the human body; cosmetic medical devices; drug sustained release systems; in vitro supplies.

Room-temperature vulcanized silicone rubber

The difference between room-temperature vulcanized silicone rubber and high-temperature vulcanized silicone rubber is that it is based on polysiloxane with a small molecular weight, and can be vulcanized into an elastomer at room temperature or with a little heating under the action of a crosslinking agent and a catalyst.

RTV silicone rubber is composed of base rubber, crosslinking agent, catalyst, filler, and so on. The main applications are:

1. Achitechive

1) Silicone structural adhesives are mainly used for structural or non-structural bonding between metal and glass of glass curtain walls.

2) It can directly connect the glass with the surface of the metal component to form a single assembly component, which meets the design requirements of the curtain wall with fully hidden or semi-hidden frames.

3) Structural bonding and sealing of insulating glass.

Neutral weather-resistant adhesive:

1). It is suitable for weather-resistant sealing of the exterior of various curtain walls, especially recommended for weather-resistant sealing of glass curtain walls, aluminum-plastic panel curtain walls, and dry-hanging stone materials;

2). Seam sealing between metal, glass, aluminum, ceramic tile, organic glass, and coated glass;

3). Joint sealing on the surface of concrete, cement, masonry, rock, marble, steel, wood, anodized aluminum, and painted aluminum. Primer is not required in most cases.

2. IT

It can be encapsulated, poured, impregnated, coated, bonded, etc., moisture-proof, dust-proof, arc-proof, corrosion-proof, shock-proof, and impact-proof. Potting protection for electrical components. Adding thermal conductive filler, it can be used as a heat dissipation adhesive for electrical appliances.

3. Electricity

It is mostly used for bonding and filling of glass bricks, glass ceramic bricks, and anti-corrosion alloy materials in chimneys and pipeline anti-corrosion lining systems of thermal power plants; bottom sealing of thermal power plant equipment, and facilities with anti-corrosion systems.

4. Medical Industry

Silicone rubber is non-toxic, tasteless, and physiologically inert. It can be used as anti-noise earplugs and soft liners for denture bases. Used as a dental impression material. For facelifts and make-up.

5. Auto aviation

Automotive window seals, electrical and electronic connectors, gaskets, reflector lights, exhaust pipes, and adhesive seals for instruments.

Gaskets for form-in-place are developing rapidly. Wide operating temperature, good impact resistance, good compression set, good sealing, low cost, and simple process.