Introduction

Silicone rubber molding is an industry standard method used to produce high quality rubber components for products ranging from seals and gaskets to complex medical tools and automotive components. Compression molding stands out among its various molding methods as the go-to technique for producing top quality silicone rubber bellows and diaphragms.

Bellows and diaphragms are essential components in industries across many fields, from healthcare to automotive to aerospace manufacturing, used for pressure regulation, fluid control and vibration dampening. Compression molding has proven an efficient process to mass produce these parts consistently with consistent quality while meeting strict tolerance controls – in this article we explore this method as applied to silicone rubber bellows and diaphragms, its advantages and disadvantages as well as different molds used during rubber compression moulding molding processes.

Compression Molding Process for Silicone Rubber

Compression molding manufacturing process in which heated silicone rubber material is placed into a mold cavity at high pressure under compression until it assumes the shape of its intended mold cavity. After curing at a certain temperature for an allotted period of time, the mold is opened up and removed to release its part for de-molding.

Compression molding for silicone rubber offers many advantages, including producing large quantities with consistent quality and tolerances that meet or surpass customer specifications, cost-efficiency for low volume production runs, versatility when using liquid silicone rubber materials to produce complex geometries with tight tolerances, as well as wide selection of materials that allow use during silicone compression molding process.

However, compression molding does have its drawbacks. For one thing, it can be time-consuming and labor-intensive when compared with injection molding; and controlling its curing process may prove challenging; excess material may need trimming off from final products as a result of excess curing processes. Yet compression molding remains popular choice when producing custom molded rubber components such as bellows and diaphragms for bells or diaphragms.

Suitability of Compression Molding for Bellows and Diaphragms

Compression molding is an ideal method for producing bellows and diaphragms made of silicone rubber, thanks to its ability to produce parts with consistently high quality and tight tolerances. Furthermore, the compression molding process enables production of parts of various thicknesses with complex geometries – an essential feature when manufacturing bellows or diaphragms.

Compression molding offers several distinct advantages when compared to other molding methods such as injection or transfer molding, such as injection. Compression molding works better for producing parts with thicker walls or complex shapes than its competitors such as injection and transfer molding; moreover, its lower production volume requirements mean it makes more economical use of material resources than its alternatives.

On the other hand, injection molding is ideal for high volume production runs and creating parts with very thin walls or intricate details. Furthermore, this process is much faster compared to compression molding, producing less waste material while producing faster parts overall. Transfer molding offers advantages of both techniques but requires more complex equipment and tooling setup.

Compression molding remains an more cost effective solution for means of producing high-quality bellows and diaphragms made of silicone rubber, particularly when producing lower volume runs with parts with different thicknesses or complex geometries.

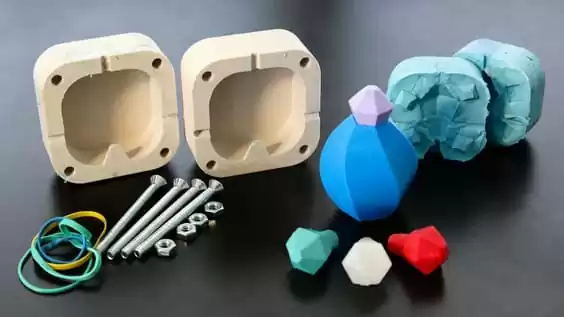

Types of Compression Molding Molds

There are various compression molding molds available to produce high-quality silicone rubber parts like bellows and diaphragms, including bellows. Some of the more frequently used molds include:

Open Molds: These molds are the easiest type to use and consist of two flat plates placed together to form a cavity within which mold parts can be produced with uniform thickness and easy de-molding. Open molds are well suited to producing simple parts with uniform thickness that require quick de-molding processes.

Closed Molds: Closed molds are designed for producing more complex parts with non-uniform thickness and intricate geometries, like those made out of non-woven fabrics or intricate plastic molds. They consist of multiple plates designed to open and close in specific patterns in order to produce desired shapes.

Compression Transfer Molds: Compression transfer molds resemble traditional closed molds in that material is transferred between cavities during molding; these molds can help create parts with variable thickness or material content as well as overmolding applications.

The choice of mold material and design considerations depends on a number of factors, including the complexity of the part, material used, production volume required and desired production volume. Common materials used for molds include aluminum, steel and epoxy which each provide their own set of advantages and disadvantages such as cost, durability and ease of machining.

Design considerations for silicone rubber compression molded molds include draft angles, wall thickness and gate location. Draft angles must be sufficient for easy de-molding while wall thickness must remain uniform to maintain consistent part quality. Gate location plays a significant role in controlling material flow into the mold cavity to avoid air pockets or defects that would compromise part quality.

Selecting the proper compression molding liquid injection molding, and material are integral parts of producing high-quality silicone rubber parts such as bellows and diaphragms, with ease and consistency of production in mind. Design considerations must also be kept in mind to guarantee consistent part quality while keeping costs down during production.

Materials Used for Compression Molding

Silicone rubber is an extremely flexible synthetic elastomer material commonly used in compression molding to produce bellows and diaphragms. As a synthetic elastomer material, silicone rubber offers several unique characteristics including heat resistance, chemical resistance and electrical insulation properties – not to mention it can come in an assortment of colors and hardness levels for production purposes.

silicone rubber has many advantages over other elastomeric materials like natural rubber and EPDM, including heat resistance that reaches 200degC. Furthermore, its chemical resistance makes it perfect for high temperature applications as it resists acids, bases, and other potentially corrosive substances.

Natural rubber is more cost-effective, and is typically preferred in applications where cost is the primary consideration. It boasts excellent elasticity and abrasion resistance, making it suitable for tires and seals; however, due to low chemical and temperature resistance it may limit its application in certain applications.

EPDM is another widely used elastomer with excellent weather resistance and low-temperature flexibility, often found in automotive applications such as weatherstripping and gaskets. Unfortunately, EPDM lacks heat-resistance as well as chemical resistance compared to its silicone rubber counterpart and cannot withstand temperatures above 140 F for extended periods.

Overall, silicone rubber remains an appealing material choice for compression molding due to its unique properties and versatility; however, material selection will ultimately depend on individual application needs and performance criteria.

Production Process for Compression Molding Bellows and Diaphragms

Compression molding bellows and diaphragms require multiple steps for production: from mold design and preparation, through material selection, molding and curing processes and finally de-molding.

Mold Design and Prep: To begin the molding process, it is first necessary to design a mold according to your preferred bellows or diaphragm shape. Your mold must accommodate its thickness, shape, any undercuts or features on your part as well as being clean and lubricated to ensure smooth molding process.

Once a part is selected, it’s essential to select an appropriate material such as silicone rubber, liquid silicone rubber or other elastomerics before mixing any additives or colorants necessary for desired properties.

Molding and Curing: Once placed into a mold cavity, material is compressed under high pressure with a hydraulic press before being heated at an ideal temperature for extended curing – this ensures it possesses all desired properties, such as flexibility and hardness – prior to release for production.

De-Molding: Once the part has set up, its mold should be opened up and removed from it. Any excess material must be trimmed away, while final touches such as surface texturing or painting can be applied as desired.

Compression molding can accommodate both low and high volume production runs, with manual presses generally serving lower volumes while automated presses may be more suitable for higher ones. Your project requirements and part volumes will determine which press is suitable.

Compression molding bellows and diaphragms involves several key stages, from mold design and preparation, material selection and mixing, molding, curing, de-molding and de-molding. It can be utilized both for low volume production runs as well as large ones that feature parts with variable thicknesses or complex geometries.

Applications of Compression Molded Bellows and Diaphragms

Compression-molded bellows and diaphragms are integral components in numerous industries, including healthcare, automotive, aerospace and industrial manufacturing. They’re used for pressure regulation, fluid control and vibration dampening.

Compression-molded bellows and diaphragms are used extensively throughout the medical industry, often as components for devices like breast pumps, inhalers and syringes. Diaphragms on breast pump diaphragms made from silicone rubber must withstand repeated usage as well as regular cleaning processes without degrading over time.

Automotive industries use compression molded bellows and diaphragms extensively in components such as fuel pumps, brake systems and engine management systems. Diaphragm valves also play an essential part in controlling fluids and gases flow within automotive environments.

Compression-molded bellows and diaphragms are integral parts of many aerospace components such as air conditioning systems and fuel systems, made from materials like silicone rubber or EPDM to withstand extreme conditions associated with space travel.

Compression-molded bellows and diaphragms have multiple uses in industrial manufacturing, from pumps and pressure sensors to pressure regulators and molded rubber and boots – which protect equipment from dust and debris – made with compression molding technology.

Compression-molded bellows and diaphragms play an indispensable role in many industries and applications, accommodating high pressure, controlling fluid flow, and dampening vibrations – key characteristics essential for running systems efficiently and smoothly.

Advantages of Compression Molding for Bellows and Diaphragms

Compression molding offers numerous advantages when it comes to manufacturing high-quality bellows and diaphragms, including:

High Quality: Compression molding offers parts with consistent quality and precise tolerances due to its use of high pressure molding techniques and uniform material distribution during molding processes.

Compression molding offers tight tolerance control to ensure each part produced reflects a consistent level of accuracy and precision.

Cost-Effective: Compression molding offers an economical option for low volume production runs as it doesn’t require expensive injection molding equipment or large amounts of material.

Compression molding can utilize various materials, including liquid silicone rubber. This enables manufacturers to produce parts with complex geometries and tight tolerances with this process.

Comparative to injection and transfer molding methods, compression molding offers several distinct advantages over their counterparts. It is ideal for producing parts with thicker walls and more complex shapes while its low volume production runs do not necessitate costly equipment or large amounts of material.

On the other hand, injection molding is ideal for high volume production runs as it produces parts with extremely thin walls and intricate details. Furthermore, this process is faster compared to compression molding and produces less waste material; transfer molding combines elements of both techniques but requires more complex equipment and tooling for implementation.

Compression molding remains an effective means for producing top-grade bellows and diaphragms due to its consistent manufacturing with tight tolerance control.

Conclusion

Compression molding is an indispensable manufacturing method for producing top-quality silicone rubber bellows and diaphragms, providing consistent quality with tight tolerances – an essential factor when producing parts requiring tight quality control measures.

Compression molding can be an economical solution for low volume production runs and rapid prototyping. It supports the use of diverse materials – including liquid silicone rubber – as well as producing parts with complex geometries and tight tolerances.

Overall, compression molding is a reliable and flexible means of producing high-quality bellows and diaphragms used across industries including medical, automotive and aerospace. Thanks to its ability to consistently produce top-tier parts at low costs, compression molding provides manufacturers an ideal way to produce silicone rubber components with tight tolerance control while remaining cost effective.