Mold silica gel is generally composed of five components: base rubber, crosslinking agent, catalyst, filler, and additives. Usually, the base rubber, crosslinking agent, and filler are made into one component, and the catalyst is a separate component.

Known as two-component vulcanized silicone, RTV-2 room temperature curing silicone. Its vulcanization is carried out at room temperature. Adding an appropriate amount (1%-5%) of catalyst (curing agent) to the main silicone rubber component can produce a cross-linking reaction and form a flexible and elastic colloid.

The use of mold silicone

Mainly used in the toy gift industry, craft gift industry, furniture decoration and decoration industry, character reproduction, architectural decoration and decoration industry, resin handicraft industry, unsaturated resin handicraft industry, candle craft, plastic toy industry, gift stationery industry, gypsum craft gift Industry, silicone mold manufacturing industry, bold industrial products, simulated animal and plant sculptures, Buddha carving crafts and other industries for product reproduction and mold making.

Mold silica gel is generally composed of five components: base glue, crosslinking agent, catalyst, filler, and additive. Usually, the base glue, crosslinking agent, and filler are made into one component, and the catalyst is taken as a single component. Therefore, mold silica gel is also known as a two-component vulcanized silica gel and RTV-2 room-temperature cured silica gel.

The vulcanization is carried out at room temperature, and the main glue component is added with an appropriate amount (1%-5%) of the catalyst (curing agent) two groups of compounds can produce a cross-linking reaction, forming a flexible, elastic colloidal.

Selection of mold silicone

According to the operation method, if the perfusion mold (molding types) can choose the silica gel with a hardness of 20 degrees or 40 degrees, specifically:

Features of 20-degree hardness mold silicone: for small handicrafts, low viscosity, good fluidity, easy to operate, easy to defoam, good tensile tear strength, easy to pour.

Features of 40-degree hardness mold silicone: for large-scale products, low viscosity, good fluidity, easy operation, easy defoaming, good tensile tear strength, easy to pour.

The structure of mold silicone

Mold silica gel is generally composed of base rubber, crosslinking agent, catalyst, filler, and additives. In theory, as long as there are the first three components, mold silicone can be made, but to obtain a certain strength, “filler” is generally necessary, and “additive” depends on the situation.

Usually, the base, crosslinker, and filler are made as one component and the catalyst as a separate component. The ratio of the catalyst component to the main rubber component is generally between 1% and 3%, and the speed of the gelling reaction can be adjusted by adjusting the catalyst ratio.

The characteristics of mold silicone

1. Mold silicone rubber should have good operability.

2. Silica gel has better fluidity, low viscosity, and easy operation.

3. The shrinkage rate of silicone rubber is as small as possible.

4. The tensile strength of silicone rubber is better.

5. The silicone mold made cannot be deformed.

6. The hardness of silicone rubber should be suitable for the product.

7. High-temperature resistance, more mold turning times, longer service life, better acid and alkali resistance, and aging resistance.

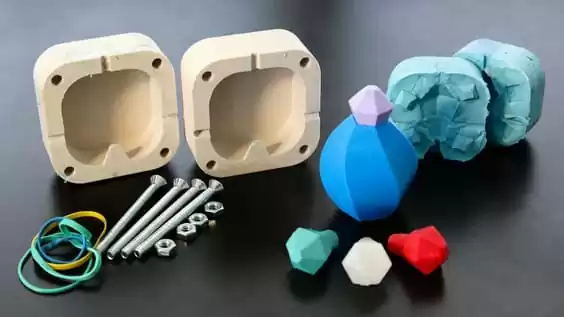

The production method of silicone mold

1. Use a plastic bowl to hold 500g glue, add 1.5% curing agent at room temperature, stir well and set aside.

2. Lubricate the master mold base with a release agent.

3. Surround the well-lubricated mother base with wooden strips, and the wooden strips should also be treated with a release agent. The gap in the middle should be 2-4cm.

4. Slowly pour the prepared glue along a fixed pouring point, and shake it from time to time to remove the air inside.

5. After the glue is fully cured in 60 minutes, surround it with wooden strips, leave a 4cm gap, and remove the original wooden strips.

6. Mix 1000g of gypsum powder with water and pour it into the wooden frame until it is full (the wooden frame should be divided into two parts with plastic sheets to facilitate demolding).

7. After 20 minutes, the wooden strips are removed, and the mold is completed.

Precautions:

1. The amount of curing agent should be determined according to the temperature, and the amount of curing agent should be reduced when the temperature is high. If the curing agent is used too much, the mold will become hard and brittle; if the curing agent is used too little, the operation time will be prolonged.

2. To prevent the change in the physical properties of the silicone mold, it is recommended not to add silicone oil.

3. To achieve the best use effect of your mold, please store the mold for at least 24 hours before use.

4. The hard mold can also be made of resin.

The operation method of mold silicone

1. Stir the silica gel and curing agent evenly:

The appearance of mold silicone is a flowing liquid, component A is silicone, and component B is a curing agent. Example: Take 100 grams of silica gel and add 2 grams of curing agent (Note: The silica gel and curing agent must be stirred evenly.

If they are not stirred evenly, one part of the mold will be cured and one part will not be cured, and the silica gel will appear uneven drying and curing. It will affect the service life of the silicone mold and the number of mold turning times, and even cause the mold to be scrapped.

2. Vacuum and air bubble treatment:

After the silica gel and the curing agent are evenly stirred, carry out vacuuming and air bubble removal. The vacuuming time should not be too long. Under normal circumstances, it should not exceed ten minutes.

The silica gel becomes one piece and cannot be painted or poured, so the silica gel is wasted, and the silica gel can only be poured into the trash can and retake the silica gel to do it again.

3. Brushing or operation process:

The silicone that has been evacuated through air bubbles is applied by brushing or pouring. Pour it on the product (note: the product or model to be replicated before pouring the silica gel must be sprayed with a release agent or a release agent).

Then paint the silica gel on the product, the brushing must be even, after 30 minutes paste a layer of gauze fiber weft cloth to increase the strength and tension of the silica gel. Then apply a layer of silica gel, and then paste a layer of gauze fiber weft cloth, so that it will be fine after two times.

Only in this way, the service life and the number of mold turning times of the opened silicone molds will be relatively much improved, which can save costs and improve efficiency.

4. The production of the outer mold:

The general method and material used are to surround the mold with rubber board or wood board and fill the mold cabinet with gypsum as soon as it is filled. The other method is to paint with resin, and paste a layer after brushing a layer of resin. Glass fiber cloth, then brush and paste, repeat two or three layers to complete the outer mold of the mold.

5. The operation method of filling mold or pouring mold:

Filling mold or pouring mold is used for relatively smooth or simple products, and there is no mold line to save labor and time.

6. Fragmentation mold or sheet mold operation method:

Before painting, apply a layer of release agent or release agent to the product or model you want to copy,) After waiting for 30 minutes, paste a layer of gauze or glass fiber weft cloth on the surface to increase the strength, and then paint after the second layer of silica gel and other silica gels are dried, make an outer mold, and the outer mold can use materials such as gypsum or resin.

Common processing technology problems

1. The number of mold turning is less

Too much silicone oil is added in the processes of making the mold, and the silicone oil destroys the molecular weight of the silica gel, so the mold will have fewer turning times and is not durable.

If you want to make a small product with a complicated pattern, if you use high-hardness silicone to open the mold, there will a phenomenon that number times the mold is turned less, because the silicone will be brittle and easy to break when it is too hard.

On the contrary, if you use low-hardness silicone to make molds for building products, the result will also be unsatisfactory. Because the silicone is too soft, it’s tensile and tears strength will be reduced, and the mold made will be deformed, so the number of times mold turns will be reduced.

The quality of the silicone molding glue itself is very good. There is no good or bad liquid silicone rubber, only suitable or not. This situation will not happen if we use silica gel suitable for the hardness of the product to make the mold.

2. Die burning occurs

Because unsaturated resin and resin products are added with peroxide curing agents, a lot of heat will be generated when they meet the resin reaction. Generally, the curing time of resin is 3 minutes, so the mold should be demoulded as soon as possible after 3 minutes to prevent the silicone mold from being damaged. The phenomenon of mold burning occurs.

3. There is a phenomenon that the surface is dry and the inside is not dry

Mold silica gel is a condensation-type silica gel, which is solidified by absorbing moisture in the air. During the production process of silica gel, the moisture is evaporated to dryness, and this phenomenon will occur if the appropriate amount of water is not added.

Solution: This phenomenon is not a product quality problem, but because there is no control over the moisture content, the storage period of the silica gel is improved, and some phenomena will appear after long shelf life. As long as the silica gel is used, add 0.05% water in an appropriate amount and stir evenly. Some situations can be resolved.

4. There is a phenomenon of tension difference

Because in the process of making the mold, in order o reduce the viscosity of the silica gel and make the silica gel easy to operate, the customer adds a large amount of silicone oil to the silica gel, which will make the silica gel very soft, resulting in resistance to pull and lower tear strength.

The phenomenon of poor tensile force will cause the phenomenon that the mold is not durable, the service life is short, and the number of times turning over the mold is less.

Mold silicone itself will not emit oil. Oil emission occurs because compound silicone oil (composite of silicone oil and white mineral oil) is added during the operation because white mineral oil is a petrochemical product, not silicone oil.

5. The mold is not resistant to acid and alkali, and is not resistant to aging

In the process of making silicone molds, we suggest that existing customers should not add any silicone oil. If necessary, the amount of silicone oil added should not exceed 5% to 10%. Because too much silicone oil will destroy the molecular weight of silica gel, so the mold made will not be resistant to acid and alkali, and will not be resistant to aging.

6. There are traces, streaks, and roughness on the surface of the mold

This phenomenon occurs because the product or model to be reproduced has not been sanded or polished.

The model or product itself is not smooth or perfect enough, so if the product or model to be copied has not been polished or polished, even the best silicone mold will be unsightly and not smooth enough.

Another situation is that when the release agent is applied, the mold is not smooth if it is not evenly applied.

How to clean the silicone electroplating mold?

The electroplating mold cannot be cleaned by the ordinary sandblasting method, and local dirt cleaning should be used. Generally, it is used to clean up the accumulated dirt on individual parts of the electroplating mold.

It would be a waste of time to remove the mold from the vulcanizing machine. , At this time, we only need to use small wooden things such as chopsticks and long wooden sticks to scrape off the dirt inside the mold cavity.

The use of wooden things to remove dirt is because the hardness of wood is relatively low and will not damage the surface of the silicone products mold.

At the same time, we can dilute with an appropriate amount of caustic soda and 10 times pure water, and then take a cotton swab dipped in diluted caustic soda water to wipe the dirt and make it fall off. Or the cleaning method to remove the dirt on the whole mold.

Put the electroplating mold of silicone products in a vulcanizing agent or an oven and heat it to 160°C, then put the caustic soda into boiling water and stir evenly according to the ratio of caustic soda and water 1:100, and then put the prepared liquid medicine is poured on the mold, and at the same time, it is scrubbed with a copper brush to remove the dirt on the surface of the mold cavity.

During the brushing process, the liquid medicine is continuously sprayed to prevent the mold from drying out. After scrubbing, rinse the mold with plenty of water to completely rinse off the liquid medicine, and then quickly dry the moisture on the surface of the mold with an air gun. Wear protective gloves during the entire operation to avoid burns.

Room temperature vulcanization addition type mold silicone: the condensation type mold silicone has lower strength, and the latter has higher strength.

Its vulcanization mechanism is based on the addition reaction (hydrosilation reaction) of the vinyl group (or propylene group) on the end group of the silicone raw rubber and the silicon hydrogen group on the cross-linking agent molecule.

In this reaction, a hydride-functional polysiloxane is used as a crosslinking agent (curing agent) and chloroplatinic acid or other soluble platinum compounds are used as a platinum catalyst. The vulcanization reaction is carried out at room temperature.

No by-products are emitted. Since no low-molecular substances are released during the cross-linking process, the addition-type RTV silicone rubber does not shrink during the vulcanization process.

This type of vulcanizate is non-toxic, has high mechanical strength, excellent stability against hydrolysis (even under high-pressure steam), good low compression molding set, low flammability, deep vulcanization, and vulcanization speed can be controlled by temperature, etc.

Advantages, so it is a type of silicone rubber that is vigorously developed at home and abroad. In addition, changing the amount of curing agent will not change the curing speed, but will affect the physical properties after curing. Therefore, the measurement of the curing agent must be done as accurately as possible.

Selection of mold opening method and mold line selection of mold silicone

The choice of mold opening form and the choice of mold line are very important.

1. It is for the convenience of taking molds;

2. The mold line should be selected without affecting the overall effect of the product;

3. It does not affect product quality. For example, the position of the mold line of the waterscape series products is too high, a lot of material is required when sealing the mold line, and the product is prone to cracking;

4. It is to reduce the process operation procedures, such as opening half molds.

To prevent silica gel from flowing around, fix the mold with wooden squares or planks in a regular range.

When opening the mold, use wood and oil sludge to separate the first part. It is required that there is no gap between the oil sludge and the mold and that the surface of the oil sludge is smooth and flat.

After the preparation of the above work is completed, then apply vaseline or spray release agent on the plaster mold or model. For smooth products, it is required to use a clean cotton cloth to dip Vaseline evenly on the model and keep it for 30 minutes.

The first kind fully absorbs Vaseline, and then wipes the surface of the model with a clean pure cotton cloth, requiring a bright surface; while the textured product only needs to be evenly coated with Vaseline, and the silica gel is adjusted according to the formula.

When mixing silica gel, it should be stirred in an irregular direction, so that the curing agent and silica gel can be fully mixed, and air can be mixed into the glue as much as possible. For smooth products, it is best to vacuum once when applying the first layer of glue. 7-8 seconds.

After the silica gel is prepared, the mold should be made in time. Pour the glue on the highest part of the mold by trickling, let it flow naturally, and use an oil paintbrush to fix the place where the flow is not in place.

If it is a piece of mold, the silica gel will not only fill the entire product but also brush evenly on the glue. Each product should be brushed with at least three layers of silica gel. The thickness of each layer of silica gel is 1mm. In the process of brushing silica gel, it is required that each layer is cured before another layer can be applied.

When brushing the third layer, add a layer on top of the second layer. Layer gauze to increase the strength of the silicone. The thickness of the silicone part of the whole mold is controlled at 3-4mm according to the different requirements of the product size, and the width is not greater than the product width of 60mm. The silica gel begins to solidify in 20 minutes.

Product classification of mold silicone

1. Cultural stone silica gel

2. Gypsum mold silicone

3. Handicraft mold silicone

4. Soap soap mold glue

5. Candle molding silicone

6. Silicone tire mold

7. Food mold glue

8. Shoe mold silicone

9. Resin drill glue

10. Human body mold silicone