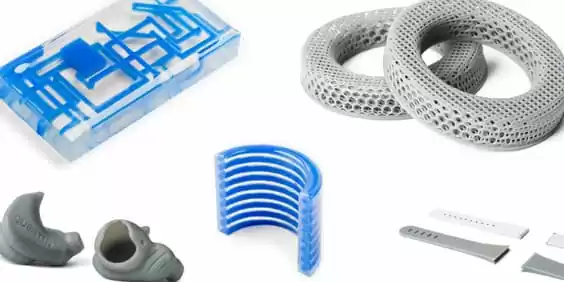

Silicone mold is one of the most simple methods in rapid mold. Generally, the 3D printed prototype is remolded with silica gel, but the life is very short only about 10-30 pieces.

It has good elasticity and replication performance, with silica gel compound mold can not consider the angle of the die, will not affect the dimensional accuracy, has a good segmentation, without the upper and lower mold can be directly integrated casting, and then along the predetermined parting line cutting, take out the mother mold can be.

Room-temperature vulcanized silicone rubber is divided into two types adding molding and condensation. The raw material and formula are made of special mold silica gel, which is sold in the form of double packaging.

The A component is the rubber material and the B component is the catalyst. When preparing, the room temperature, strength, and hardness of the mold should be considered to determine the proportion of AB components by weight.

At room temperature of 20-25 degrees, A: B = 100:1.5; When the chamber is low (but not lower than 10 degrees), add 0.1-0.3 of B component appropriately; If the room temperature is too high, reduce group B by 0.1-0.3.

The specific method is: according to the mold volume to determine the total amount and then A, and B components according to the proportion of the accurate weighing, placed in the vessel stirring evenly, that is.

Operation method of mold silica gel

1. Mold silica gel and curing agent and stir evenly. Mold silicone appearance is the flow of liquid, part A is silica gel, and part B is firming agent, for example, take 100 grams of silica gel, and add 2 grams of curing agent (note: silicone and curing agent must stir well if there is no uniform mixing, mold can appear uneven drying curing condition, and affect the service life of the silicone mold, and the number of rolling over, and even cause mold scrapped.

2. Vacuum exhaust bubble treatment. After the silica gel and curing agent are stirred evenly, the vacuum exhaust bubble is evacuated. The vacuum time should not be too long, generally not more than 10 minutes, otherwise, the silica gel curing crosslinking reaction, can not be brushed or perfusion, resulting in material waste.

3. Brushing operation process. The silica gel discharged by the bubble is poured on the mother mold by brushing or perfusion (before the brush mold or perfusion, the mother mold is hit with an isolation agent or release agent), the brush mold must be uniform, 30 minutes after sticking a layer of sand cloth or glass fiber cloth to increase the strength and tension of the mold;

Then the second brushing, and then paste a layer of gauze or glass fiber cloth, and then silica gel brushing, after this treatment, the mold has more service life and die turning times, long service life, cost saving, and improve efficiency.

4. Making the outer mold. The generally used method is the mold around with plastic board or wood surrounded, one is to use plaster will fill the mold frame can, another is the use of resin coating way, brushing a layer of resin, brushing a layer of glass fiber cloth, and then brush and paste, repeated two or three layers can be completed.

5. The ratio of silica gel (silicone, silicone) and curing agent is reflected. It is suggested that the amount of curing agent should not exceed 5%. The greater the proportion of the curing agent, the faster the curing time, the more brittle the mold, and the shorter the service life.

Also according to the product and process requirements, the right amount of silicone oil can be added to make the mold better. Pay attention to the silicone oil should not be excessive (5%-10%), otherwise, it will affect the tension and hardness of the silicone mold.

Silica gel mold production matters need attention

1. Component B is a catalyst, which is susceptible to moisture hydrolysis, so the lid should be tightly covered after use.

2. As soon as A and B components are mixed, the chemical reaction starts immediately, and the viscosity gradually rises and cannot be stopped. To avoid waste, it should be prepared according to the dosage, with the use, and should be used immediately after mixing without delay.

3. The mixture ratio of groups A and B is related to the speed of the chemical reaction and the performance of the mold. The more B components, the faster the reaction, and the higher the strength and hardness of the product, but the toughness will be reduced, so the weighing requirements are accurate.

4. Before preparation, the A component should be stirred up and down evenly, and then weighed.

5. Pouring method is suitable for the relief class, brushing method is suitable for three-dimensional mold production. For casting relief molds, the length and width should be larger than the original carving length and width of 4-6CM.

The border should be flat and the inside smooth. When pouring, place the border on a clean glass plate, and then put the prototype in the frame, leaving a 2-3CM gap on each side (mold silica gel 25-35 yuan /KG).

Solutions for bubbles in the production process of silica gel mold:

(1) Improve the design of the flange groove and exhaust system;

(2) Increase the pressure of the press;

(3) Reduce the amount of release agent and spray evenly;

(4) Material control moisture;

(5) You can try to add some antifoaming agent;

(6) Use cold runner;

(7) Vacuum exhaust with a vacuum machine, and an exhausted groove can be added to the mold.