“The traditional thermally conductive materials are mostly metals such as Ag, Cu, A1 and metal oxides such as A12O3, MgO, BeO and other non-metallic materials such as graphite, carbon black, Si3N4, A1N.

With the development of industrial production and science and technology, people have put forward new requirements for thermally conductive materials, hoping that the materials have excellent overall performance.

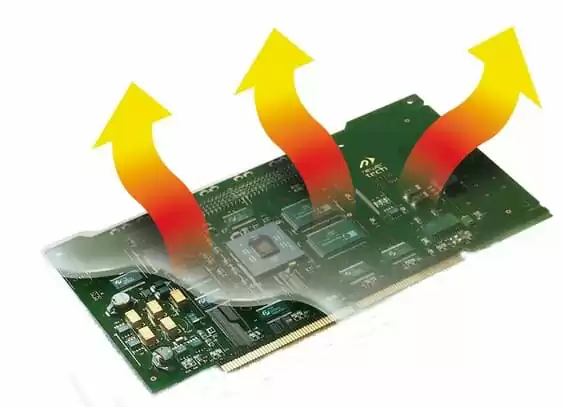

For example, in the electrical and electronic field, due to the rapid development of integration technology and assembly technology, the volume of electronic components and logic circuits has been reduced by thousands of times, which requires high thermal conductivity insulating materials.

In recent decades, the field of application of polymer materials has been expanding, and the replacement of various materials used in traditional industries, especially metal materials, with synthetic polymer materials has become one of the directions of the world’s scientific research efforts.”

What is a thermally conductive silicone film?

Thermally conductive silicone film is a kind of thermally conductive medium material which is synthesized by a special process with silicone as the base material and various auxiliary materials such as metal oxides.

Thermally conductive silicone rubber is a polymer composite material with silicone resin as the bonding material and filled with thermally conductive powder to achieve the purpose of thermal conductivity.

Commonly used thermally conductive silicone film matrix materials and fillers

Silicone resin (basic raw materials)

1. Insulation thermal conductivity filler: aluminum oxide, magnesium oxide, boron nitride, aluminum nitride, beryllium oxide, quartz, and other silicone plasticizers

2. Flame retardant: magnesium hydroxide, aluminum hydroxide

3. inorganic coloring agent (color distinction)

4. cross-linking agent (bonding performance requirements)

5. catalyst (process molding requirements)

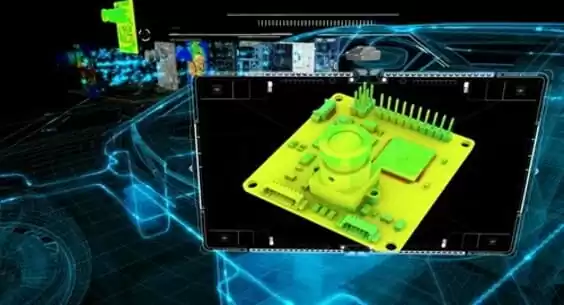

Note: The heat conduction silicone film plays the role of thermal conductivity, forming a good thermal path between the heating body and the heat sink, and the heat sink, structural fixings (fan), etc. together to form a heat sink module.

Fillers include the following metal and inorganic fillers.

1. Metal powder filler: copper powder. Aluminum powder. Iron powder. Tin powder. Nickel powder, etc.

2. Metal oxides: aluminum oxide. Bismuth oxide. Beryllium oxide. Magnesium oxide. Zinc oxide.

3. Metal nitrides: aluminum nitride. Boron nitride. Silicon nitride.

4. Inorganic non-metal: graphite. Silicon carbide. Carbon fiber. Carbon nanotubes. Graphene. Beryllium carbide, etc.

Classification of thermally conductive silica gel

Thermally conductive silicones can be divided into thermally conductive silicone gaskets and non-silicone gaskets. The electrical insulation performance of the vast majority of thermally conductive silica gel is ultimately determined by the insulation performance of the filler particles.

1. Thermally conductive silicone gaskets

Thermally conductive silicone gaskets are subdivided into many subcategories, each with its different characteristics.

2. Non-silicone gaskets

The non-silicone gasket is a high thermal conductivity material, self-adhesive on both sides, and shows low thermal resistance and good electrical insulation characteristics under low compression force when used in electronic component assembly. It can work stably at -40℃~150℃. Meet the requirements of UL94V0 flame retardant grade.

Thermal conductivity mechanism of thermally conductive silica gel

The thermal conductivity of thermally conductive silica gel depends on the interaction between the polymer and the thermally conductive filler. Different kinds of fillers have different thermal conductivity mechanisms.

1. The thermal conductivity of the metal filler

The thermal conductivity of metal filler is mainly by electron movement, and the process of electron movement is accompanied by the transfer of high heat.

2. The thermal conductivity of the non-metallic filler

The thermal conductivity of non-metallic fillers mainly relies on phonon thermal conductivity, and its thermal diffusion rate mainly depends on the vibration of neighboring atoms or bonding groups. Including metal oxides, metal nitrides, and carbides.

How to use thermally conductive silicone film?

Thermal conductive silicone film is generally added to the structural design and hardware and circuit design at the early stage of design.

The factors to be considered are thermal conductivity consideration, structural consideration, EMC consideration, vibration and sound absorption consideration, installation test, etc.

1. Choose excessive heat dissipation solution: electronic products now to the short and thin trend, the general use of passive heat dissipation, the traditional heat sink solution is the main; now the trend is to eliminate the heat sink, the use of structural heat sink (metal bracket, metal shell);

Or heat sinks solution and heat dissipation structural parts program combination; in different system requirements and environments, choose the best cost-effective solution.

2. If the heat sink program is, it is not recommended to directly use the low thermal conductivity of double-sided adhesive; also not recommended to use the thermally conductive silicone grease that does not have the function of shock absorption; recommended using the metal hook-up or plastic pushpin to operate, choose 0.5mm thickness of the thermally conductive silicone film with the use of these two programs easy to install and operate.

But also can not be used by the glue, the transfer heat dissipation effect will be much better than the thermal conductive double-sided adhesive, more safe and reliable. The total cost, including unit price, manpower, and equipment will be more competitive.

3. The choice of heat dissipation structural parts class heat dissipation, it is necessary to consider heat dissipation structural parts in the contact surface of the structure of the form of local protrusion, local avoidance, etc., in the structure of the process and the size of the thermally conductive silicone film to choose a good balance.

Under the condition that the process allows, it is recommended not to choose a particularly thick thermal conductive silicone film. Here it is generally recommended to use single-sided adhesive for the convenience of operation, and to stick the adhesive side to the heat dissipation structure;

Here we should especially choose a good compression ratio to ensure a certain pressure to the thermally conductive silicone film.

The thickness of the thermally conductive silicone film must be greater than the theoretical gap between the heat dissipation structure and the heat source, generally 1mm – 2mm more.

The choice of heat dissipation structure parts should also be considered in the PCB layout of the location of components, hey, ht and package form, you can place some heat sources regularly, reducing the cost of heat dissipation structure parts.

How to choose thermal conductive silicone film?

Thermal conductivity selection

The choice of thermal conductivity depends mainly on the size of the heat source power consumption, as well as the size of the heat sink or thermal structure of the heat dissipation capacity.

General chip temperature specification parameters are relatively low, or more sensitive to temperature, or heat flow density is relatively large (generally greater than 0.6w/cm3 need to do heat dissipation treatment, the general surface is less than 0.04w/cm2 only needs natural convection processing can be) these chips or heat sources need to be heat dissipation treatment and try to choose a high coefficient of thermal conductivity of thermal conductive silicone film.

The consumer electronics industry generally does not allow the chip junction temperature higher than 85 degrees, it is also recommended to control the surface of the chip in the high-temperature test to less than 75 degrees, the entire board components are also basically commercial grade components, so the internal temperature of the system at room temperature is recommended not to exceed 50 degrees.

The first appearance of the surface or the end customer by the surface can contact the recommended temperature at room temperature should be less than 45 degrees. Choosing a thermally conductive silicone film with high thermal conductivity can meet design requirements and preserve some design margin.

Note Heat flow density: is defined as the amount of heat passing through a cross-section per unit area (1 square meter) per unit time (1 second).

The junction temperature is usually higher than the case temperature and the device surface temperature. Junction temperature can measure the time required to dissipate heat from the semiconductor wafer to the package device shell and the thermal resistance.

The factors affecting the thermal conductivity of the thermal silicone

1. The type and characteristics of the polymer matrix material

The outstanding thermal conductivity of the matrix material is very high, the better the dispersion of the filler in the matrix and the better the combination of matrix and filler, the better the thermal conductivity of the thermally conductive composite material.

2. Type of filler

The higher the thermal conductivity of the filler, the better the thermal conductivity of the thermally conductive composite thermal interface materials.

3. Shape of filler

Generally speaking, the order of easy to form thermal conductivity path is whisker > fiber > flake > granule, the easier the filler is to form a thermal conductivity path, the better the thermal conductivity.

4. The content of the filler

The distribution of the filler in the polymer determines the thermal conductivity of the composite. When the filler content is small, the thermal conductivity effect is not obvious; when the filler is too much, the mechanical properties of the composite material will be greatly affected.

When the filler content increases to a certain value, the fillers interact with each other to form a net-like or chain-like thermal conductive network chain in the system, and the thermal conductivity is best when the direction of the thermal conductive network chain is consistent with the direction of heat flow. Therefore, there is a critical value of the amount of thermally conductive filler.

5. Bonding characteristics of filler and substrate material interface

The higher the degree of combination of filler and substrate, the better the thermal conductivity, the selection of a suitable coupling agent for the surface treatment of the filler, and the excellent thermal conductivity can be increased by 10% -20%.