Vietnam has the world’s fifth largest area under rubber cultivation with about 940,000 hectares. According to a report by the Vietnam Rubber Association, Vietnam ranks third in the world in terms of production.

Exports of natural rubber products (rubber blocks and latex concentrate), rubber products (tires, medical supplies and shoe soles) and rubber timber have grown significantly, from $2.9 billion in 2015 to about $9.5 billion in 2021.

The rubber production of small farmers in Vietnam has exceeded that of large farmers by more than 8%. This is also higher than the average production of the member countries of the Association of Natural Rubber Producing Countries.

This is because most smallholder farmers use high-yielding rubber varieties for their crops. Over the past 10 years, the area of rubber plantations has been decreasing due to the conversion of rubber to other crops or industrial development by many companies.

Are you looking for Silicone Rubber Molded Manufacturers and Suppliers in Vietnam? We have compiled the Top 5 Silicone Rubber Molded Manufacturers and Suppliers in Vietnam list for you to pick as below:

1. RPSV IMEX CO LTD

Location: Dong Nai Province, VietNam

Company type: Manufacturing

Year founded: 1996

The number of employees: 200-299

Main Services: Moulded Part, Extrusion, Plastics, Steel Bonded Part, Seals And Gaskets, Sheeting

RPSV IMEX CO LTD Company Profile

With over 10 years of experience in the rubber industry, their factories capabilities include rubber compound master batch, compression molding, injection molding, rubber extrusion, TPE extrusion, rubber sheeting and plastic molding.

They are manufacturer for rubber, plastics, steel components for various applications. Their home office and factories are located in Viet Nam. They design products in house and manufacture to your needs.

Their factories capabilities include rubber compound master batch, compression molding, injection molding, rubber extrusion, TPE extrusion, rubber sheeting and plastic molding.

The various types of rubber that can be molded include natural rubber, as well as synthetic rubber such as neoprene, foam rubber, EPDM, silicone rubber, and liquid silicone rubber.

They’ll thoroughly analyze your needs to recommend the most effective material for corrosion-resistant, heat-resistant, flame-resistant, ozone resistant and made with varying degrees of properties such as rigidity, flexibility, durability, and strength.

They established their manufacture plant with Asian value for money and western ethics to provide their value customers with competitive and innovative products.

2. Jhao Yang Rubber

Location:Bac Giang, VietNam

Company type: Manufacturing

Year founded: 1971

The number of employees: 200-299

Main Services: Rubber parts, Custom parts, Silicone and parts, Mold manufacturing, Production, Research and development.

Jhao Yang Rubber Company Profile

Established in 1971, they specialize in manufacturing silicone and rubber products. Their major products cover 3 sectors – rubber, rubber bonded to metal, and silicone.

Under the company’s policy of “Insisting on Quality & Customer Oriented”, they constantly introduce more advanced production equipment to increase quality and efficiency. In addition, they continuously improve their manufacturing processes according to ISO regulations. They also implement rigorous quality control so as to fully meet customers’ requirements for quality.

As nowadays business competition is becoming more serious than ever before, Jhao Yang will be dedicated to modern business management based on their current foundation. In the meantime, they will continuously upgrade their technical capabilities to strengthen their competitiveness in the market.

3. Vina Rubber Co., Ltd

Location: Hanoi City, Vietnam

Company type: Manufacturing

Year founded: 1996

The number of employees: 200-299

Main Services: Molds making, Rubber Parts, Rubber Extrusion

Vina Rubber Co., Ltd Company Profile

Vina Rubber Co., Ltd | Vietnam custom rubber parts manufacturer, trustworthy rubber parts supplier on supply chain. Produce rubber molding parts, silicone seal, rubber bonding to metal parts, medical O’rings seals, FDA Food-contact materials, rubber gaskets, rubber grommets, extrusion profiles…

Vietnam is one of the leading supply centers with many international manufacturing brands, stability of politics and economics, labor cost is one of cheapest countries in the world. So that, those are reasons why their product is high quality and more competitive.

They produce precision molding rubber parts, silicone seal, rubber bonding to metal parts, micro rubber and silicone components, molding rubber & silicone seals.

Producing method with injection; vacuum compression; transfer. Mold tool is made by myself so they can provide all solutions to customers, new technology of automatic machines so they can produce rubber orders with big volume, their quality also meets to global supply chain standard.

4. TOPSHENG SILICONE

Location:Hoc Mon Hcm, ViETNAM

Company type: Manufacturing

Year founded: 1979

The number of employees: 100-199

Main Services: Design&Engineer, Mold Making, Manufacturing capability, Quality Management

TOPSHENG SILICONE Company Profile

TOPSHENG SILICONE are from multi-international cooperations who have many years experiences on material science, product design, silicone rubber mold making and massive production management, they have invested a lot on the man power training,test tools, mold-making & production equipments and advanced softwares.enabling the advancement of industrial technologies.

They focus on producing hign volume components and turnkey custom molded, precision silicone components designed to safeguard harsh environment connectivity.

TOPSHENG SILICONE’s skilled workforce offers customers a unique combination of technical expertise,advanced manufacturing and something seldom available from silicone companies-total solution for silicone rubber products.

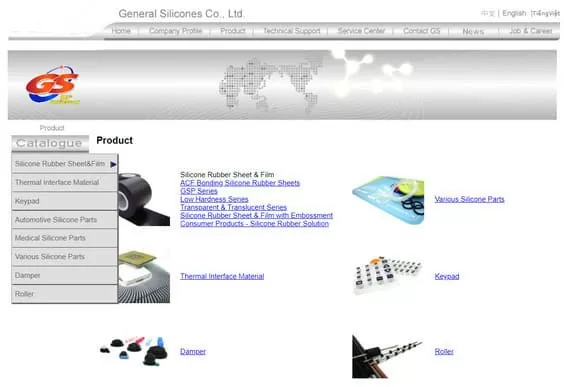

5. General Silicones

Location: Thái Bình, Vietnam

Company type: Manufacturing

Year founded: 1970

The number of employees: 100-199

Main Products: Silicone Rubber Sheet&Film,Silicone Parts, Automotive Silicone Parts, Medical Silicone Parts

General Silicones Company Profile

Hsinchu, September 10, 2020 – Specialist silicone products manufacturer, General Silicones (TPEx: 4730), is perfectly placed to deliver the benefits of the new EU-Vietnam Free Trade Agreement (EVFTA) to European automobile makers, automotive industry suppliers, consumer electronics and other industries. General Silicones (GS) can achieve this thanks to the company’s state-of-the-art highly-automated factory in Vietnam (a direct offshoot of GS’s Taiwan headquarters) which opened in 2018, manufacturing silicone rubber products and materials.

If You’re Looking For More Silicone Rubber Molded Manufacturers, Also You Can Choose A Chinese Injection Mold Supplier: Zetar Mold

Zetar Mold

Location: Shanghai, China

Company type: Manufacturing

Year founded: 2005

The number of employees: 201-300

Main Services: Silicone Rubber Product Design, Silicone Rubber Mold Making, Silicone Rubber Product Manufacturing, Assembly, Post-processing and Packaging

Other Products: Plastic Injection Mold, Plastic Injection Molding Manufacturing, Overmolding injection molding China, Insert Molding Products, 3D printing and CNC Prototyping

Zetar Mold Company Profile

Over the past 17+ years, we have built our company into a Silicone Rubber Product Design, Silicone Rubber Mold Making, Silicone Rubber Product Manufacturing, Assembly, Post-processing and Packaging all in one juggernaut.

Through steady organic growth and strategic acquisitions, we’ve seen decades of excellent performance. Scroll through our history to see some of our corporate highlights.

We Have Our Own Factories In Shanghai, Jiangsu And Zhejiang. In 2020, COVID-19 Spread Globally And China Was Also Greatly Affected.

In Order Not To Affect The Production Schedule Of The Projects, They Started To Set Up Sub-Factories In Jiangsu and Zhejiang.

Conclusion

Finding a trustworthy silicone rubber manufacturer and supplier nowadays is not that easy, especially since many new manufacturers have emerged just to keep up with the trend. But hopefully, their list was able to help you find the one that best suits your requirements. It is recommended to do a background check before creating partnerships with manufacturers because they will play a huge part in the success of your business.